LEAD PRODUCT DESIGNER - Advanced Anomaly Detection

bp

Overview

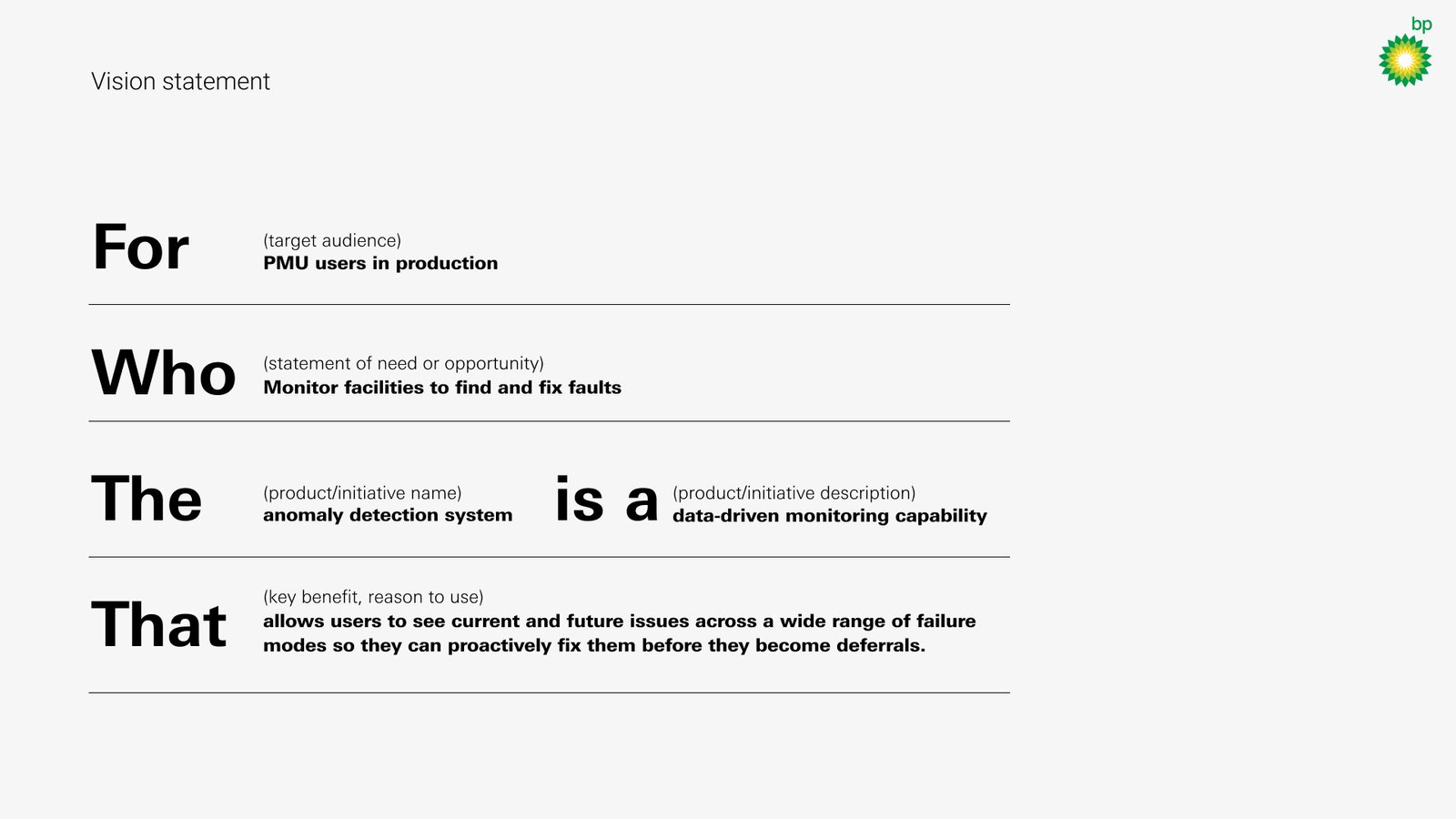

Total deferrals in production were 138 mboed a day in 2018 worth approx US$2.4 billion in lost revenue. About half of that was due to unplanned deferrals.

We believe there is an opportunity to reduce unplanned deferrals. Using machine learning for production surveillance, we can spot faults and respond proactively to look after our facilities.

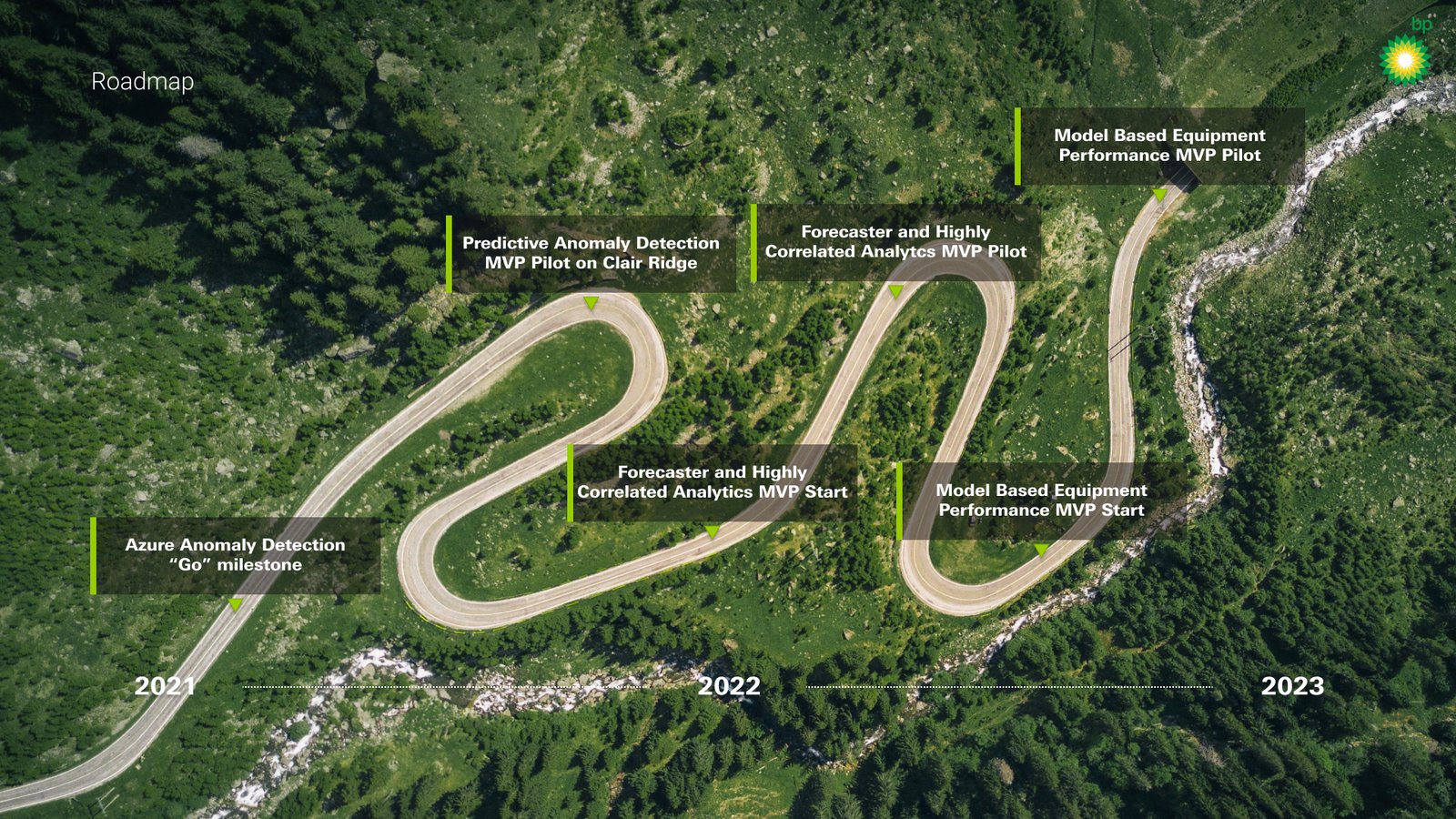

By bringing this digital capabilty in-house using Azure, we can deploy more capability faster in new locations more flexibly and transparently to allow users to drive value.

Opportunity

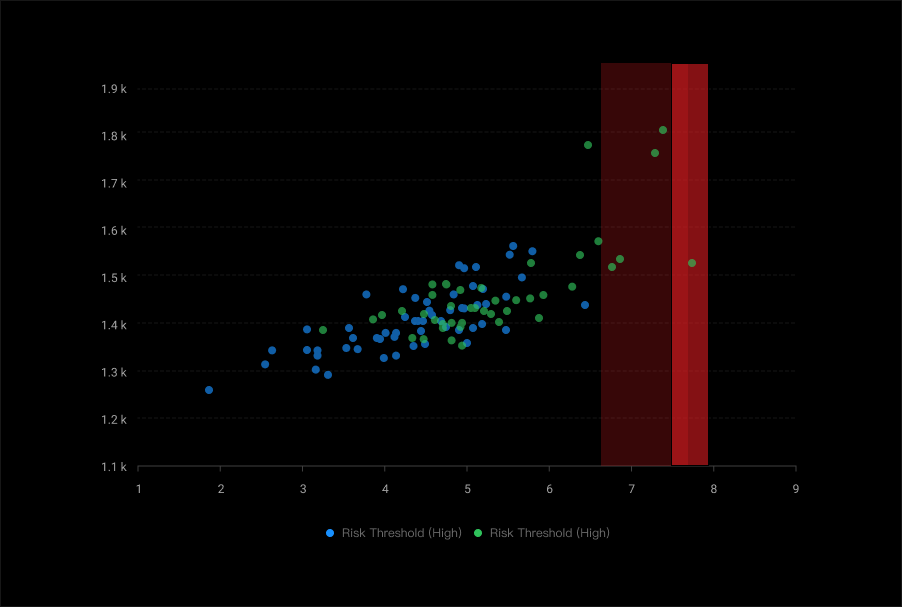

Predictive Anomaly Detection supports Production Management by providing machine learning analytics as digital tools which support PMU teams to reduce future deferrals.

Machine learning has a proven track record of value delivery through Spark Cognition in production surveillance, accounting for up to 0.5 mboed on the first two assets (Atlantis and ETAP in 2020).

This proven value can scale to 8 mboed to prevent around U$150 million per annum in lost revenue when deployed to our 33 hubs.

Potential capabilities

Multiple analytics capabilities in one system to deliver significant business value

- Single Variable Micro Analytics

Monitor key sensors for abnormal reading without human intervention . - On / Off Mode Analytics

Monitor Facilities, Systems and equipment for on or off state without human intervention. - Highly Correlated Analytics

Monitor highly correlated equipment sensors for correlation breakdown without human intervention. - Predictive Anomaly Detection

Detect equipment faults and performance degradation using multivariate ML models to predict and prevent future deferral events . - Model Based Equipment Performance

Use Vertex data streaming to create performance models for unit analytics . - Forecaster

Predict what will happen in a 90-day time horizon based on current/proposed operating conditions.